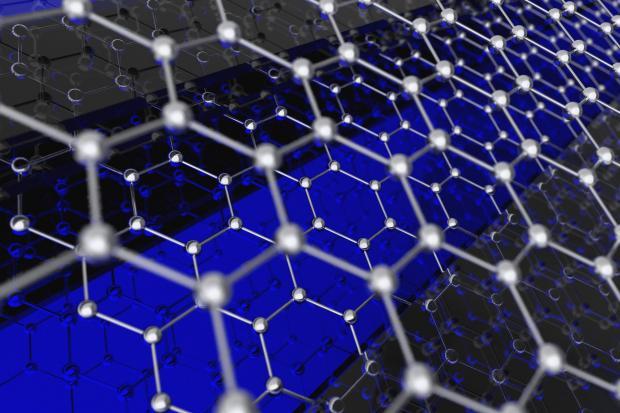

Graphene is the world’s thinnest material at just a single atom thick, or one-million times thinner than a human hair, but is 200 times stronger than steel and conducts heat and electricity better than copper.

Graphene is usually produced by a process known as chemical vapour deposition, or CVD, which turns gaseous reactants into a film of graphene on a special surface known as a substrate.

The research team at Glasgow used a similar process, but used commercially-available copper foils, often used as the negative electrodes in lithium-ion batteries, as a surface on which to create high-quality graphene.

Researchers also observed the surface of the copper used provided an excellent bed for the graphene to form upon.

The university’s technique of producing graphene not only reduced the cost but offered a stark improvement in the electrical and optical performance of the material, compared to the older, more expensive, process.